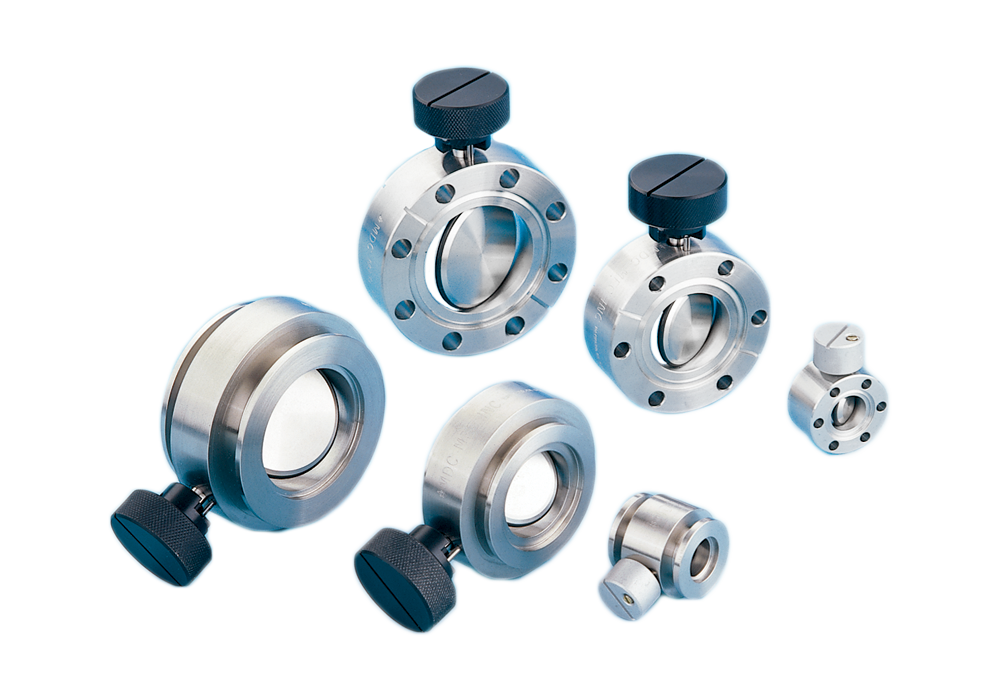

Valves

Valves

Vacuum technology places high demands on the function and reliability of valves that are often needed in large numbers in a plant. These requirements are met only if proper shut-off devices are installed for each application, depending on the construction method, mode of operation, and size. Furthermore, in the design and operation of vacuum processes, factors such as the flow conductance and leakage density of valves are of

great importance.

Valves are designed so that they do not lower the pump speed. Hence, when fully opened, their conductivity in the rough and medium vacuum regions is equal to the corresponding pipe sections. For example, the conductance of a straight valve will correspond to the conduit of a bent tube with the same nominal bore and angle.

Similarly, the conductivity of a molecular flow valve (i.e., in the high and ultra high vacuum ranges) is so high that no significant difference occurs. Actual values for conductance of various components are often stated in our catalogs. To meet high density requirements, our high quality vacuum valves are designed so that the gas molecules reach the valve shaft surface, not transferred from the outer atmosphere to the vacuum during operation. The valves are equipped with metal bellows to isolate the valve shaft from the atmosphere, or alternatively they are fully encapsulated, that is, only static seals exist between the atmosphere and the vacuum. Our valves are thus adapted to work in vacuum environments where there is low tolerance for leakage.

Read more under the respective valve section and in our product catalogs.

If you want advice or help finding the right valve, do not hesitate to contact us at Low2High Vacuum.