Pioneering dry vacuum technology keeps Food Packaging and Processing lines running at all times!

Rovagnati S.p.A. trust in Leybold vacuum solutions for their production processes

Over 1000 employees, six production plants, and one swine breeding facility, typical for northern Italy, Rovagnati is strongly one of the first Italian companies in cured meats. Rovagnati is

the biggest producer in the Parma region and one of the biggest in Italy, with four branches in Belgium, France, United States, and Germany granting full control on raw material and production knowhow. They are market leader with the Gran Biscotto brand for quality cooked ham, and today some of its products such as the Snello Gusto e Benessere lines are amongst the most appreciated ones in Italy.

Born in the 1940’s, Paolo Rovagnati saw the need for food goods producers arise in the 60’s and started the production of cured meats, specializing a few years later in cooked ham. In the 80’s, he established the Gran Biscotto brand which is characterized by the fire mark on the rind, which today represents the Flagship product. Today the excellence of the products produced by Rovagnati is well known to many consumers.

Since the beginning, High quality and tasty products prepared in a healthy way are the passion of this company. Rovagnati engages in the production, taking care of all steps from the selection of meats, all raw materials, as well as packaging and regional distribution. The Rovagnati brand stands for the commitment of the company towards the consumers. Since 2014, the company has started a project of diversification, acquiring many historical brands such as Berkel and recently Pineider and finally during last November opened a new small and cozy bistrot in the center of milano‘s heart right in front of the charming church of S.Simpliciano, in the famous Via Garibaldi in Brera district of fashion and design, taking the famous brand into direct customer contact.

How did the collaboration between Rovagnati and Leybold start?

The collaboration started in the early 90’s, Rovagnati has always been very careful with the choice of its partners and Leybold had been chosen as historical company for vacuum technology in foods and its notoriety and quality of the products.

Which are the essential requirements for the pumps and the vacuum systems used in the food processing?

The pumps need to grant a vacuum value needed for the processes of packaging and tumbling of the cured meats and need to grant repeatable values and maintain them during the production process.

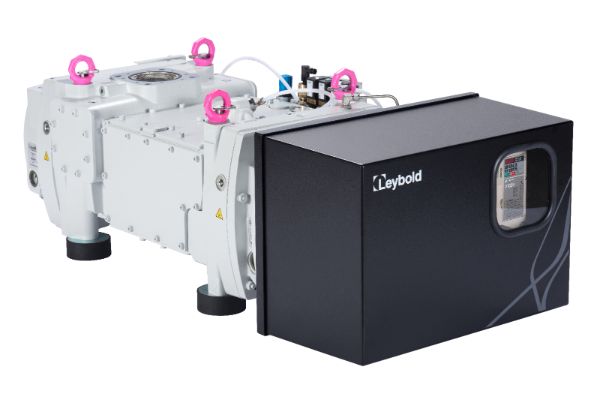

How is a typical vacuum pumping system composed in food processing and why does Rovagnati buy the dry screw pumps DRYVAC?

The system is composed by the piping, the vacuum trap, and the pump. In the packaging process, by the booster pump and the traditional pump. Rovagnati buys the DRYVAC for its high performance in vacuum, repeatable during time, low maintenance costs and in some applications a considerable energy saving.

Has Rovagnati had a production increase thanks to the system conceived by Leybold?

Did Rovagnati achieve savings thanks to this new system?

In some applications we have had a decrease of the time to reach the right vacuum level of approximately 20%, improving the total packaging time.

The first system has been installed 4 years ago and until now we have never had a production stop due to breakdowns or problems.

Rovagnati dedicates maximal attention to the quality of its products. How do you grant it and safeguard it?

The use of dry vacuum pumps helps avoiding contamination of the packed product? The high quality of the products for Rovagnati is a vocation, a precise choice for which we apply a real and sustainable culture of precision, which is implemented in all the productions processes.

Dry pumps vs lubricated pumps: what are the relative advantages for you?

The first one grant low maintenance costs, energy saving and vacuum repeatability.

Why is the vacuum produced by Leybold essential in terms of higher quality?

Leybold pumps help maintain the high quality standard for our products which btranslates into quality for our consumers.

How are projects handled? How does Leybold take care of the vacuum packaging systems of Rovagnati during their lifecycle?

Rovagnati has an internal maintenance department which handles the ordinary service for the pumps. For the new systems, Leybold provides to Rovagnati all the construction data for piping and performances.

Service impact: is it quick and up to your expectations?

Until now we never needed it.