Leybold and G. Mondini, a joint solution.

T hanks to over 45 years of experience in tray sealing innovation, G. Mondini has become a leading company, with more than 15,000 installations all over the world and constant and continuous collaboration with major food industry enterprises in five continents.

From the most complex and complete line for the production and packaging of “food and no-food” to the single closing machine in different types of packaging technology, G. Mondini’s offer can stand any comparison in terms of quality and reliability. The new Trave with the revolutionary Platform Technology® concept is the most advanced tray sealer in the world. Designed with unrivalled robustness and reliability, the TRAVE satisfies the most stringent food safety and hygiene requirements providing outstanding flexibility without any compromise in efficiency. The ability to deliver multiple packaging technologies in Heat Seal, MAP, Vacuum skin, Double Decker, Skin Protruding, Mirabella, Stretch Seal, Map rigid lid, Blow Moulded Jars and now the brand new Darfresh® on Tray, Slimfresh®, Slicefresh® and Zero® technology on a tray sealing machine is unique giving customers the ability to offer different types of packages to meet their customers’ needs. Flexibility, due to a fast changing consumer, has become paramount and the G.Mondini Platform® Technology expresses the maximum flexibility achievable on a packaging machine. Coupled this with the Mondini latest invention, the PLATFORMER®, Mondini has delivered the most cost effective and most flexible packing system ever. G. Mondini PLATFORMER® allows the lowest possible plastic consumption, delivering outstanding trays, with a clear cost benefit. Simply combining the Trave Platform together with the Platformer, G. Mondini has demonstrated how the best product differentiation without compromise can be achieved. A unique system which allows customers to drive down their final pack cost, embracing a unique differentiation and tiering capability, thanks to the full integration of the Platformer into the exclusive Mondini Platform technology. Security, experience, performance, and flexibilty are for sure the main reasons why all the major food companies all over the world have chosen G. Mondini as a partner for their business.

Mondini is a worldwide leader for the production of complete filling and packaging lines for the food industry. How long is the working relationship between Leybold and G. Mondini?

After a lot of work done together to develop the best possible integration, which lasted several months, G. Mondini and Leybold started to offer a joint solution round about 18 months ago.

How do you select your technology partners?

What drives us mostly in the selection of our partners and what it is in our opinion the most important aspect to consider when making a choice, is the commonality of values, such as transparency and integrity. The commonality of goals is also paramount for us, to enable us to guarantee the satisfaction of our customers, by delivering them the best performing solution.

Why did you select Leybold as a partner for vacuum technology?

We have found in Leybold the above values and in Mr. Raffaello Ghislotti especially a very skilled person and absolutely devoted to understanding our needs and to finding a solution for them. Consequently, the offering which has been presented to us by Leybold guarantees optimum and robust performances and thanks to Leybold team work an extremely good integration, which delivers benefits to our customers.

Mondini is offering different platform technologies for different packaging processes/ products. Which technologies / products requires a vacuum from Leybold?

Leybold products allow to cover all needs for packaging and processing systems: from traditional oil-sealed pumps to the newest dry technology which allows to break down management costs like energy expenses and avoiding onerous special oils. For our customers all of this means not only saving money but also saving the environment: a vision that both Mondini and Leybold share for the future of all of us.

What are your essential requirements for the vacuum systems/pumps used in your products? (cost, efficiency, security, flexibility, output, foot print, service, dry pumps)

For us, the most important thing is the absolute performance and the consistency of the result.

What is the typical pump/pumping system from Leybold you use in view of these requirements? Why?

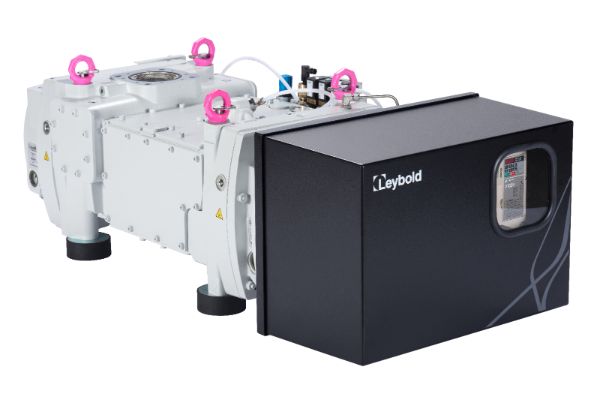

DRYVAC DV650 PFPE, because it is able to satisfy any kind of process. This type of pump indeed is able to reach maximum performances with skin packaging, but being it certified for High O2 also, it allows our customers to use it for skin but also for MAP applications.

How does Leybold care for your vacuum equipment over the entire life cycle?

Leybold is present all over the world with both service centers, expert technicians and prepared sales support. Their presence, capillarity and skillfulness are nowadays a must for all the companies which believe in a sustainable growth without giving a chance to unexpected fortuities.

What are the particular requirements that packaging systems have to fulfill in the future and what is the special role of the vacuum technology?

Food safety is absolutely paramount, together with food quality, flexibility and efficiency. With Leybold, we have found a way to deliver all the above to our customers: – through the performances, therefore with the guarantee of consistency of results with the minimal level of millibar, we can grant food safety and the food quality of the products packed in our machines; – thanks to the reliability of the Leybold products, we can increase our efficiency; – thanks to the dual High O2 performance, we can grant the flexibility of working with both VSP and MAP.

Mondini has customers worldwide: how did they find the Leybold pumps?

Each single customer where the Leybold pumps have been installed, has been extremely satisfied