Dry vacuum pumps

Generating a vacuum with dry pump technology is a modern method with many advantages.

Here are examples of two of the key benefits of dry vacuum technology:

During operation, no oil is in contact with the gas pumped through the dry vacuum pump, which minimizes the risk of possible contamination of the processes.

New modern models of the dry vacuum pumps are often much more energy-saving compared to older models.

Low2High Vacuum has collaborations with several suppliers of dry vacuum pumps.

Don’t see exactly what you are looking for in our standard range below? We have more products than those published on the website, so do not hesitate to contact us at Low2High if you have questions about our range of dry vacuum pumps, or any of our other products!

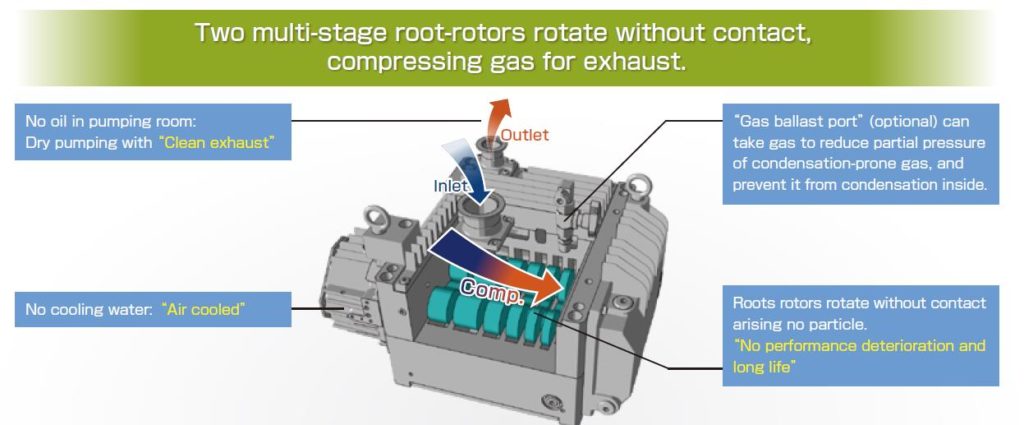

Multistage root pumps

These pumps use the proven roots technique. That is, two rotating impellers that contactlessly rotate. They are thus completely dry in the pump mechanism itself. Kashiyama Neodry series has connected six roots in series which has resulted in a low final vacuum. See picture.

Kashiyama NeoDry is sold in 6 different sizes. 7, 15, 30, 36, 60 and 300 m3 / h. All up to 60 m3 / h can be operated on single phase voltage. They are particularly distinguished by their quiet gait and low vibrations. They are also maintenance-free for at least 3 years of continuous operation, in normal applications.

Screw Pumps

The screw pump is dry compressive vacuum pumps. The principle of operation is based on two synchronized rotors which are helical (larger screw volume at the beginning and smaller at the end of the compression, see image / video) rotate while taking advantage of the decreasing available volume for the gas to exist.

As the gas reaches the pump chamber, the screws rotate and compress the gas in a continuous step, with the available volume constantly decreasing until the gas reaches the exhaust flange.

Screw pumps are available in different designs, Screwline ™ is suspended with the axles at one end while Dryvac ™ and Leyvac ™ have been through. It offers different advantages and the pumps are designed for different types of applications in general, but can also replace each other in some cases. The sizes overlap from 80 m3 / h to 5000 m3 / h. They are also available in different versions of cooling technology, both water-cooled and air-cooled. For special cases, there are also closed circulation systems for water / glycol cooling, for example where water cooling is needed but no water is available.

The dry screw pumps can be used in many applications including:

- Heat treatment (ovens)

- Coating applications (coating)

- Load chamber

- Packaging

- Drying processes

- Degassing

- Research and Development

- Automotive

- Space Simulation

energy